Reading Time: 5 Minutes

Have an inclination that there are opportunities within your supply chain but struggle to translate this to actionable realities?

It’s time to talk about supply chain context.

Supply chain context is a term we often use with clients when discussing the role of software in supply chain management. It refers to a supply chain system's ability to integrate data from multiple sources or systems, whilst providing background and meaning to that data within the full end-to-end supply chain.

Establishing supply chain context means that operations can better adapt to disruptions, provide meaningful visibility to customers, and optimise the performance of their supply chain.

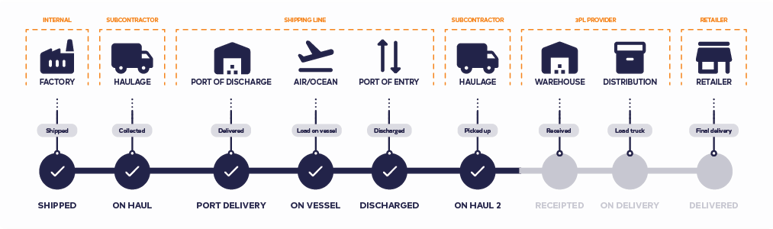

Supply chain data can be broadly split into two main categories: Supply Chain Events, and Supply Chain Context. ‘Events’ refer to something that has physically happened in the real world, and the data that relates to an Event reflects exactly that: what happened, where did it happen, when did it happen etc.

Supply Chain Context is the second part of the equation and refers to data about the thing that the Event in question is happening to. All freight that moves through a supply chain has a huge amount of data that relates to it, from the original sales order through to bills of lading, purchase orders, customs and compliance information, through to detailed information about the freight itself: dimensions and weight, barcodes, SKUs, inners, marks and numbers etc.

More concisely: ‘Context’ is the relevant data that relates to specific supply chain events.

Often the combination of several disparate systems and supply chain functions create disjointed impressions of an operation. Most of the time these systems perform their job well individually, but when taking an end-to-end perspective we lose context and the opportunities along with it.

For example, a container that has been picked up at a port may trigger a status update in a TMS, but that doesn’t mean a whole lot to your customers, partners and employees. That update needs context as to what order it is a part of, what next set of activities is about to occur, what SLAs are attached to it and, if there are any delays, how can they respond to it in real-time. However, the data for these things could be in several different systems.

Without a clear, contextualised view of the whole end-to-end supply chain, each operation within it may enter and report on data differently. Supply chain operators are often using multiple tools for different operations such as TMS, WMS and Freight Forwarding systems. Consolidating and aggregating data from a range of systems and applications is vital for cohesive management, and engendering and maintaining enterprise-wide efficiencies. Forging a 'single source of truth’ provides insight for both BAU and strategic objectives.

Creating supply chain context requires a centralised system that can integrate and consolidate all of the data from disparate systems into one clear picture. Third-party systems and applications only need to integrate with one system, instead of several, to get the necessary updates and end-to-end view they need to manage operations more efficiently, and prevent the double entry of mismatched data.

Consolidating and aggregating the supply chain data requires a proven engine and effective integration which uses built-in smarts such as rules, conventions, and consistent data objects to enable the contextualisation and presentation of all available data.

To put that into context, a current Origin customer responsible for outsourced logistics contracts processes over 13,700 job events per day (that equates to over 5 million a year!). All of these need to be formatted and contextualised in the core supply chain system to ensure their operations keep humming away and customers and partners are kept in the loop at all times.

A supply chain system like this doesn’t just magically appear. It takes years of understanding the principles of the supply chain and diligently coding those principles into the core supply chain engine which can then effectively manage all the events and automate the flow of data. The right technology partner for this will have skin in the game and proven success with these concepts resulting in faster implementations and a better overall outcome for your operation.

Once this ‘context’ is established, the data can be leveraged and presented through a variety of interfaces. Logistics service providers can see significant benefits from utilising a single user interface for operations, partners, and customers. Each user will have different access levels but are able to see and work from the same data sets. This centralised platform can also push and pull data via integration to automate and orchestrate the activities across multiple internal and external systems.

Knowing what is happening within the supply chain and communicating this knowledge to internal and external parties has become increasingly important in recent years. Customers now demand real-time information, applying pressure to often stretched networks and support systems. This places a growing emphasis on the ability to provide customers with access to the data relevant to them, but also being able to do it in an efficient way that saves valuable team members from wasting time and effort digging through many systems simply to answer the age-old question “where is my stuff?".

Establishing a set of rules that contextualises data within the supply chain enables greater transparency and accountability for all of the activities within an organisation.

“Transparency goes beyond gaining visibility into the extended supply chain. It is the process by which a company takes action on the insights gained through greater visibility in order to manage risks more effectively” (Deloitte)

Supply chain context can be difficult to achieve, we know this through our years of experience working with disparate complex systems. What we’ve built is both a foundation of technology that supports and grows with our partners, but more importantly a team that understand complexities, and are capable of delivering the right tech up front. One of our supply chain experts Will Harding, explains how Origin can help contextualise events across the end-to-end supply chain to give clients better visibility of what's happening:

Something Will mentioned; a fundamental in delivering applicable supply chain context is capturing the complete ‘story’. Part of the Origin secret sauce is the ability to grab a multitude of event data and translate it into digestible format for users and customers.

Without sharing the 11 secret herbs & spices, our approach to contextualising data and our engagement with the key stakeholders is a key component of delivering real value to organisations looking to take ownership of the end-to-end supply chain and achieve the necessary supply chain context to do so.

© Copyright 2025, Sandfield Associates Limited. All Rights Reserved. Privacy Policy